Danlex, our gold sponsor for the 4th World Airport Operations Summit, shares how advanced sensor telemetry can enhance the longevity of X-ray inspection systems through predictive maintenance. Continue reading:

Predictive maintenance is a powerful technology that is well-known in various industrial sectors [1]. But even today, there are still some industries where there's no evidence that predictive maintenance is being used at all. This is indeed the case in the X-ray security screening industry. These complex electromechanical systems are widely used for X-ray inspection in airports, border control and other security applications. As with any other critical infrastructure, the performance and health status of the X-ray screening system must be constantly monitored and analysed to achieve a flawless workflow and prevent unexpected failures.

With over 27 years of expertise in installing, servicing, and maintaining large numbers of X-ray systems, the Danlex engineering team was faced with the undeniable need for predictive maintenance solutions a long time ago. But at the time, no X-ray manufacturer or third-party company had a solution that came close to what we needed. So, with unwavering resolve, we set out to develop our own predictive maintenance solution eight years ago. The result was the development of our Predictive Maintenance for Non-Intrusive Inspection Systems (PMT4NIISTM).

Over the years, PMT4NIIS has been installed and tested on dozens of X-ray screening systems. Working in the field with real cases and solving real problems, we have encountered obstacles that we had not foreseen. All this experience has helped to drive our developments, following a scientific and engineering approach [2, 3, 4]. During this time, PMT4NIIS has proven to be a turnkey solution that offers ease of use, reliability, and customisation to seamlessly meet customer requirements.

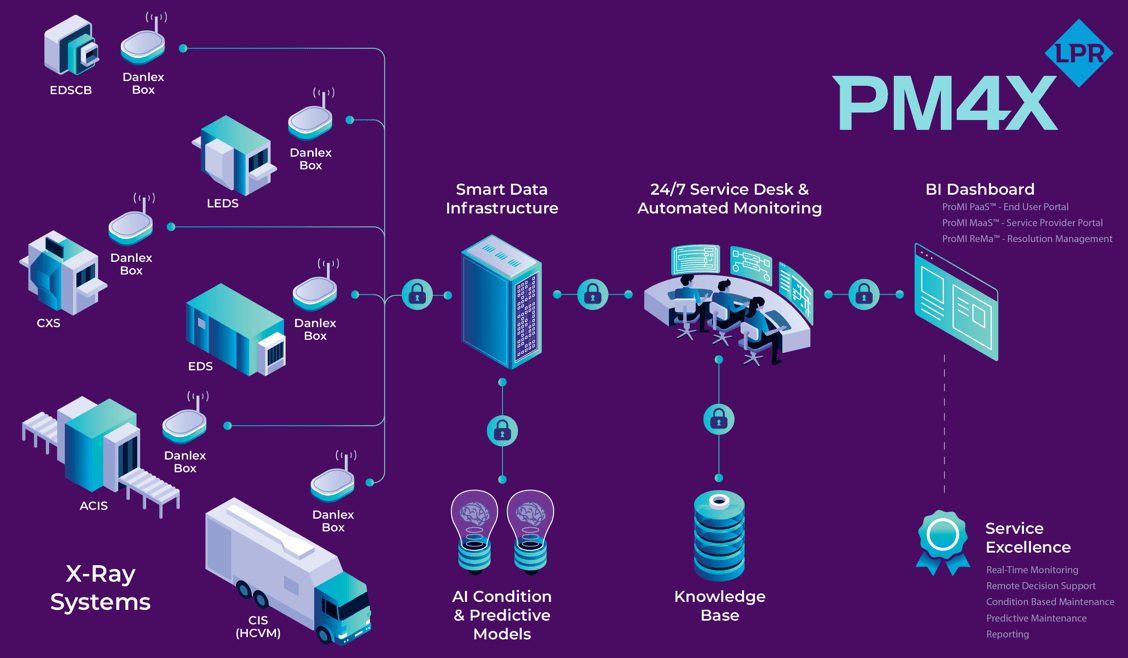

Now PMT4NIIS has evolved into PM4X LPR (Predictive Maintenance for X-ray systems – Longevity, Predictability and Reliability) with new and enhanced features.

The near real-time advanced sensor telemetry combined with statistical, AI, and ML algorithms,

PM4X LPR transforms the traditional reactive maintenance approach into a new proactive AI-driven maintenance tool. It provides the service specialist with a large amount of data in a structured BI Dashboard, including:

- Real-time status of the technical health of the X-Ray system

- Real-time values of the system’s key performance indicators

- Historical data overview to identify patterns in the deterioration of the X-ray system overtime

- Real-time results from the Condition-based and Predictive models

- Automatic alert notification system

Security

To meet the ever-increasing demands for information and cyber security, all data collected by

PM4X LPR is transmitted via encrypted channels to a secure data centre. Equipped with the latest Intrusion Prevention Systems (IPS) and Intrusion Detection Systems (IDS), we protect the entire infrastructure and data from unattended access and secure the devices against external threats.

Acknowledgement

The development of new condition-based and predictive models is currently being implemented under project No BG-RRP-2.006-0015 "Predictive Maintenance Tool for Non-Intrusive Inspection Systems (PMT4NIIS)" granted by the National Recovery and Resilience Plan of the Republic of Bulgaria.

This publication was created with the financial support of the European Union – NextGenerationEU. The entire responsibility for the content of the document lies with Danlex 78, and under no circumstances can it be assumed that this document reflects the official opinion of the European Union and the Monitoring and Reporting Structures.

Discover more about PM4X LPR and its ground-breaking impact at: https://pm4x.eu/

Authors:

Nikolay Zografov, PhD

Research & Development and IIoT Manager

Nikolay brings 20+ years of academic experience in scientific research in the field of Applied Physics, focusing on innovative measurement techniques with industrial applications. He has more than 5 years’ experience in the development and implementation of IoT systems for condition-based monitoring of X-ray inspection systems with scientific results in thermal monitoring of X-ray generators. Nikolay has authored more than 20 articles featured in SCOPUS-indexed scientific journals and conference series. He is also head of 5+ scientific research funding projects, 2 utility models, and other patent applications.

Dimitar Todorov, PhD

Innovation Manager

With a leadership role in Danlex’s product development, Dimitar orchestrates collaboration among diverse teams throughout various stages of the development lifecycle, crafts meticulous product specifications and ensures seamless fulfilment of specified requirements. Dimitar’s multifaceted contributions underscore his commitment to excellence and innovation in collaborative product development. Specialising in engineering physics, he holds a PhD in "Physical Sciences, Plasma Physics, and Gas Discharges" from Sofia University "St. Kliment Ohridski." Dimitar is the co-author of 9 articles featured in indexed foreign journals.

References:

-

Predictive Maintenance – Market Report 2017-2022, IoT-Analytics.

-

Thermal Monitoring for Condition Based Maintenance of an X-ray Generator, P. Petkov and et. Al (2023)

-

Predictive Maintenance Tool for Non-Intrusive Inspection Systems, G. Nalbotov and et. al, (2021)